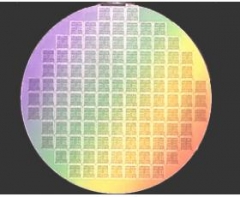

Les gabarits de pam-xiamen sont constitués de couches cristallines de nitrure de gallium (gan), de nitrure d'aluminium (aln), de nitrure d'aluminium gallium (algan) et de nitrure d'indium et de gallium (ingan) déposées sur des substrats de saphir, Les produits modèles en carbure de silicium ou silicium.pam-xiamen permettent des durées de cycle d'ép3

pam-xiamen a établi la technologie de fabrication de la plaquette de substrat gan (nitrure de gallium) autoportante, qui est pour uhb-led et ld. développé par la technologie d'épitaxie en phase vapeur (hvpe), notre substrat gan a une faible densité de défauts.

pwam développe et fabrique des substrats semi-conducteurs composés de cristaux d'arséniure de gallium et wafer.we a utilisé une technologie avancée de croissance cristalline, congélation verticale gradient (vgf) et gaas gaufrage technologie de traitement, établi une ligne de production de croissance de cristal, de coupe, de broyage à polissage une 3

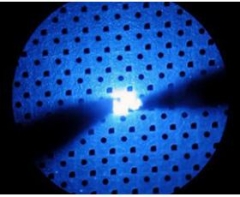

nous fournissons une épitaxie sic sur film mince (carbure de silicium) sur des substrats de 6h ou 4h pour le développement de dispositifs en carbure de silicium. sic epi wafer est principalement utilisé pour les diodes schottky, les transistors à effet de champ à semi-conducteur à oxyde de métal, les transistors à effet de champ de jonction, les tr3

pam-xiamen propose des plaquettes de carbure de silicium semi-conducteur, 6h sic et 4h sic dans différentes qualités pour le chercheur et les fabricants de l'industrie. nous avons développé la technologie de croissance de cristal de sic et la technologie de traitement de gaufrette de cristal de sic, établi une ligne de production au substrat sic fa3

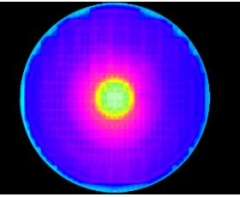

La plaquette épitaxiale à base de gan (nitrure de gallium) de pam-xiamen est destinée à l'application de diodes électroluminescentes bleues et vertes à très haute luminosité (led) et de diodes laser (ld).

Les nitrures de gallium (gan) (transistors à haute mobilité d'électrons) sont la prochaine génération de transistors de puissance. Grâce à la technologie gan, pam-xiamen offre maintenant une plaquette algan / gan hemt epi sur saphir ou silicone, et algan / gan sur saphir .

pam-xiamen est en mesure d'offrir les services suivants de plaquettes de récupération de sic.

vous pouvez obtenir notre service de technologie libre de l'enquête à après service basé sur notre 25+ expériences dans la ligne de semi-conducteur.

notre objectif est de répondre à toutes vos exigences, peu importe comment les petites commandes et comment les questions difficiles ils peuvent être, pour maintenir une croissance soutenue et rentable pour chaque client grâce à nos produits qualifiés et un service satisfaisant.

avec plus de 25 + ans expériences Dans le domaine des matériaux semi-conducteurs composés et l'exportation, notre équipe peut vous assurer que nous pouvons comprendre vos besoins et traiter votre projet de manière professionnelle.

la qualité est notre première priorité. pam-xiamen a été iso9001: 2008 , possède et partage quatre facettes modernes qui peuvent fournir une gamme assez large de produits qualifiés pour répondre aux différents besoins de nos clients, et chaque commande doit être traitée par notre système de qualité 3

Les cristaux de poly -Si sont principalement utilisés dans les cellules solaires en raison de leur faible coût. Ici, les zones de sensibilité aux longueurs d'onde de la lumière du soleil doivent être étendues pour augmenter l'efficacité technique des cellules solaires. Les films semi-conducteurs composés du groupe IV, par exemple les films Si (Ge) dopés avec des atomes de C, Ge (C, Si) et/ou Sn avec des teneurs de plusieurs %, sur un substrat Si ou Ge ont été identifiés comme des solutions potentielles à cette technique. problème. Dans cette étude, nous avons calculé l'énergie de formation de chaque configuration atomique d'atomes de C, Ge et Sn dans Si en utilisant la théorie de la fonctionnelle de la densité. La méthode "Hakoniwa" proposée par Kamiyama et al. [Materials Science in Semiconductor Processing, 43, 209 (2016)] a été appliqué à une supercellule de 64 atomes de Si comprenant jusqu'à trois atomes de C, Ge et/ou Sn (jusqu'à 4,56 %) afin d'obtenir le rapport de chaque configur...

Lire la suiteLe collage de tranches de GaAs à l'aide d'un traitement au sulfure d'ammonium (NH4)2S est étudié pour diverses structures. L'effet de l'angle de découpe de tranche sur la conductivité électrique de dispositifs de cellules solaires III-V utilisant des structures liées à des tranches de n-GaAs/n-GaAs est étudié. La diffraction des rayons X à haute résolution est utilisée pour confirmer la désorientation des échantillons collés. De plus, nous comparons les propriétés électriques des jonctions pn épitaxialement développées sur GaAs aux structures liées à la tranche de n-GaAs/p-GaAs. Microscopie électronique à transmission haute résolution (HRTEM) et microscopie électronique à transmission à balayage(STEM) sont utilisés pour comparer la morphologie de l'interface sur toute la gamme des désorientations relatives après un RTP de 600 {degré} C. Le rapport des régions cristallines bien liées aux inclusions d'oxyde amorphe est cohérent dans tous les échantillons liés, ce qui indique que le degré...

Lire la suiteLa transmission optique, la dépendance à la température de la photoluminescence (PL) et la diffusion Raman du SiC poreux préparé à partir de 6H-SiC de type p sont comparées à celles du 6H-SiC de type p massif. Alors que le spectre de transmission du SiC massif à température ambiante révèle un front relativement net correspondant à sa bande interdite à 3,03 eV, le front de transmission du SiC poreux (PSC) est trop large pour déterminer sa bande interdite. On pense que ce bord large pourrait être dû aux états de surface dans le PSC. À température ambiante, le PL du PSC est 20 fois plus résistant que celui du SiC massif. Le spectre PL PSC est essentiellement indépendant de la température. Les intensités relatives des pics de diffusion Raman du PSC sont largement indépendantes de la configuration de polarisation, contrairement à celles du SiC massif, ce qui suggère que l'ordre local est assez aléatoire. Source : IOPscience Pour plus d'informations, veuillez visiter notre s...

Lire la suiteLa transmission optique, la dépendance à la température de la photoluminescence (PL) et la diffusion Raman du SiC poreux préparé à partir de 6H-SiC de type p sont comparées à celles du 6H-SiC de type p massif. Alors que le spectre de transmission du SiC massif à température ambiante révèle un front relativement net correspondant à sa bande interdite à 3,03 eV, le front de transmission du SiC poreux (PSC) est trop large pour déterminer sa bande interdite. On pense que ce bord large pourrait être dû aux états de surface dans le PSC. À température ambiante, le PL du PSC est 20 fois plus résistant que celui du SiC massif. Le spectre PL PSC est essentiellement indépendant de la température. Les intensités relatives des pics de diffusion Raman du PSC sont largement indépendantes de la configuration de polarisation, contrairement à celles du SiC massif, ce qui suggère que l'ordre local est assez aléatoire. Source : IOPscience Pour plus d'informations, veuillez visiter notre s...

Lire la suiteUne méthode de recuit d'un cristal de CdZnTe est décrite dans cet article. Des métaux purs de Cd et de Zn sont utilisés comme sources de recuit, qui fournissent simultanément des pressions partielles d'équilibre exactes de Cd et de Zn pour CdZnTe à une certaine température. Les caractérisations révèlent que l'homogénéité est fortement améliorée et que les densités de défauts sont diminuées de plus d'un ordre, et ainsi les propriétés structurelles, optiques et électriques du cristal de CdZnTe sont évidemment améliorées par ce recuit. L'étude de la dépendance à la température de la qualité de CdZnTe après recuit montre que 1073 K est la température de recuit préférable pour CdZnTe. Il a déjà été démontré que ce processus de recuit est supérieur au recuit sous pression partielle à l'équilibre approximatif en utilisant Cd 1− y Zny alliage comme source de recuit. Source : IOPscience Pour plus d'informations, veuillez visiter notre site Web : www.semiconductorwafers.net , envoyez-...

Lire la suiteDans cette étude, une couche InP a été transférée sur un substrat Sirecouvert d'un oxyde thermique, par un procédé combinant procédé de découpe ionique et gravure chimique sélective. Par rapport à la découpe ionique conventionnelle des plaquettes InP en vrac, ce schéma de transfert de couche tire non seulement parti de la découpe ionique en économisant les substrats restants pour les réutiliser, mais tire également parti de la gravure sélective pour améliorer les conditions de surface transférées sans utiliser les agents chimiques et mécaniques. polissage. Une hétérostructure InP/InGaAs/InP initialement développée par MOCVD a été implantée avec des ions H+. L'hétérostructure implantée a été collée sur une tranche de Si recouverte d'une couche thermique de SiO2. Lors du recuit ultérieur, la structure liée s'est exfoliée en profondeur autour de la plage de projection d'hydrogène située dans le substrat InP. La microscopie à force atomique a montré qu'après des gravures chimiques sélectiv...

Lire la suiteNous passons en revue nos efforts récents sur le développement de matériaux infrarouges HgCdSe sur GaSbsubstrats par épitaxie par faisceau moléculaire (MBE) pour fabriquer des détecteurs infrarouges de nouvelle génération avec des caractéristiques de coût de production inférieur et une plus grande taille de format de matrice à plan focal. Afin d'obtenir des épicouches HgCdSe de haute qualité, les couches tampons ZnTe sont cultivées avant la croissance du HgCdSe, et l'étude de la souche inadaptée dans les couches tampons ZnTe montre que l'épaisseur de la couche tampon ZnTe doit être inférieure à 300 nm afin de minimiser la génération de luxations inadaptées. La longueur d'onde de coupure/composition d'alliage des matériaux HgCdSe peut varier dans une large gamme en faisant varier le rapport de la pression équivalente du faisceau Se/Cd pendant la croissance du HgCdSe. La température de croissance présente un impact significatif sur la qualité du matériau de HgCdSe, et une température de ...

Lire la suiteLa gravure humide est une étape importante dans la fabrication de semi-conducteurs et de plaquettes solaires et pour la production de dispositifs MEMS. Bien qu'elle ait été remplacée par la technologie de gravure sèche plus précise dans la fabrication de dispositifs semi-conducteurs avancés, elle joue toujours un rôle important dans la fabrication du substrat de silicium lui-même. Il est également utilisé pour fournir un soulagement des contraintes et une texturation de surface des plaquettes solaires en grand volume. La technologie de gravure humide du silicium pour les semi-conducteurs et les applications solaires sera passée en revue. Impact sur cette étape pour le waferles propriétés et les paramètres critiques (planéité, topologie et rugosité de surface pour les wafers semi-conducteurs, texture de surface et réflectance pour les wafers solaires) seront présentés. La justification de l'utilisation d'une technologie de gravure et d'un agent de gravure pour des applications spécifiqu...

Lire la suiteDes films homoépitaxiaux de 4H-SiC ont été développés sur des faces poreuses de 4H-SiC (0001) hors axe de 8 ° dans la plage de température par dépôt chimique en phase vapeur à partir d'un précurseur de bis (triméthylsilyl) méthane (BTMSM). L'énergie d'activation pour la croissance était de 5,6 kcal/mol, indiquant que la croissance du film est dominée par le mécanisme limité par la diffusion. Des défauts d'empilement triangulaires ont été incorporés dans le film mince de SiC développé à basse température de 1280 ° C en raison de la formation du polytype 3C-SiC. De plus, des dislocations en super-vis sont apparues sérieusement dans le film de SiC développé en dessous de 1320°C. Une morphologie propre et sans relief a été observée dans le film de SiC cultivé en dessous de 25 centimètres cubes standard par minute (sccm) débit de gaz porteur de BTMSM à 1380 ° C tandis que le polytype 3C-SiC avec des limites de positionnement doubles a augmenté à un débit de 30 sccm de...

Lire la suiteAu cours de la dernière décennie, l'utilisation de couches et de structures monocristallines de germanium (Ge) en combinaison avec des substrats de silicium (Si) a conduit à une relance de la recherche sur les défauts de Ge. Dans les cristaux de Si, les dopants et les contraintes affectent les paramètres intrinsèques du défaut ponctuel (lacune V et auto-interstitiel I ) et modifient ainsi les concentrations d'équilibre thermique de V et I . Cependant, le contrôle des concentrations de défauts ponctuels intrinsèques n'a pas encore été réalisé au même niveau dans les cristaux de Ge que dans les cristaux de Si en raison du manque de données expérimentales. Dans cette étude, nous avons utilisé des calculs de la théorie de la fonctionnelle de la densité (DFT) pour évaluer l'effet de la contrainte interne/externe isotrope ( σin / σ ex ) sur l'enthalpie de formation ( H f ) du neutre V et I autour de l'atome de dopant (B, Ga, C, Sn et Sb) dans Ge et a comparé les résultats avec ceux de Si. Le...

Lire la suiteWafer Foundry: 26321#, Liamei Rd. Lianhua Industrial Area, Tong an, Xiamen 361100, China

Informations de contact

Informations de contact luna@powerwaywafer.com

luna@powerwaywafer.com powerwaymaterial@gmail.com

powerwaymaterial@gmail.com  +86-592-5601 404

+86-592-5601 404